General

The Power of 3D‑Printed Stair Models in Our Design‑Assist Process

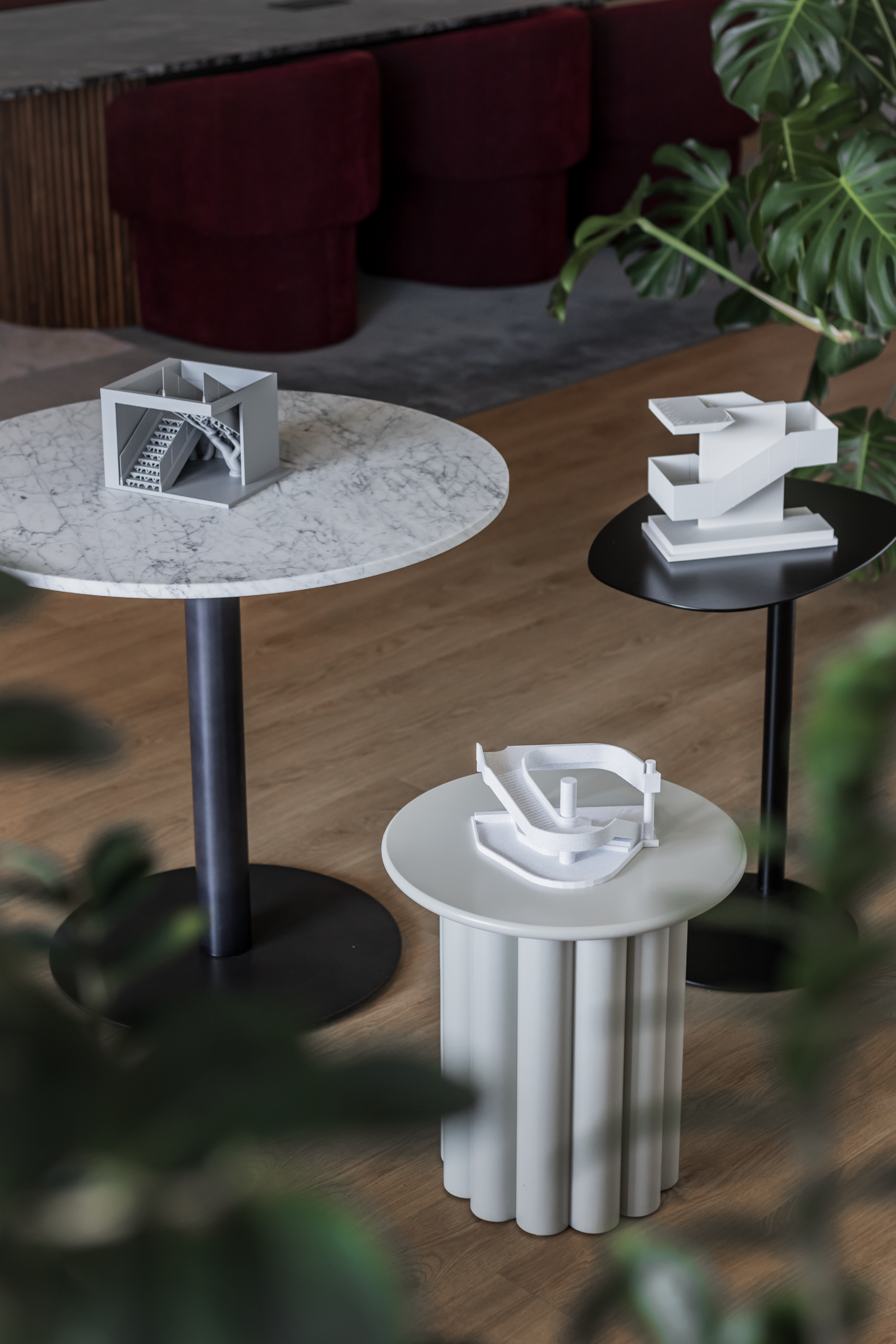

Synergi’s design‑assist methodology thrives on early, immersive collaboration, bringing together design, engineering, fabrication, and installation disciplines from the very start. A key innovation within this framework is the use of 3D‑printed stair models, which elevate concept sketches into tangible forms, detail by detail.

Synergi’s design‑assist methodology thrives on early, immersive collaboration, bringing together design, engineering, fabrication, and installation disciplines from the very start. A key innovation within this framework is the use of 3D‑printed stair models, which elevate concept sketches into tangible forms, detail by detail.

WHY 3D-PRINTED STAIR MODELS MATTER

Concrete Materialization of Design Intent

In our Concept Design phase, we craft full-scale mock-ups to “bring the design to life” within 6–10 weeks. A scaled 3D‑printed version is a low cost way to let clients literally hold and examine their stair in hand—evaluating proportions, aesthetics, and ergonomics in a way flat drawings simply can’t match.

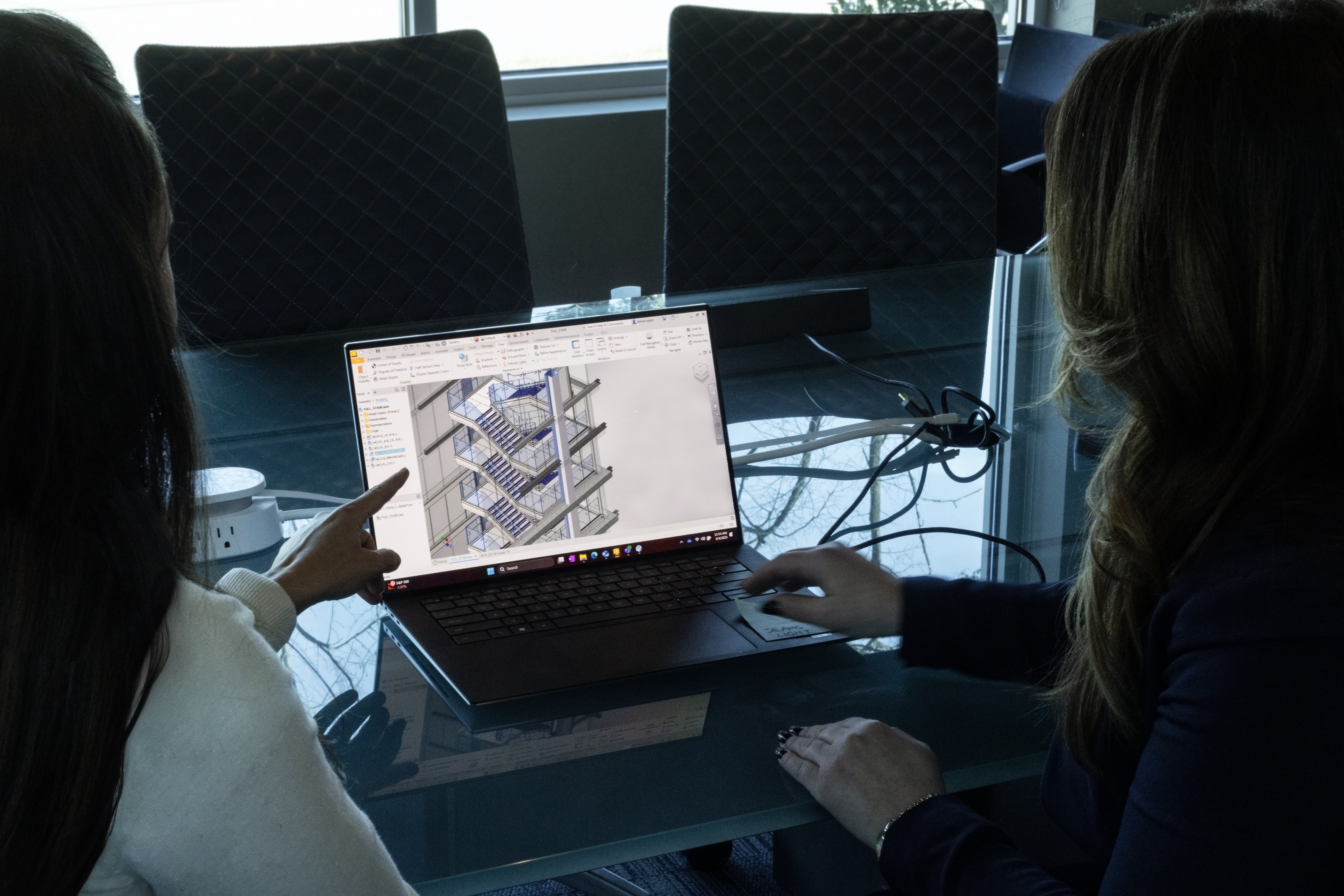

Clash‑free Coordination with BIM

Our BIM‑backed process ensures every nuance—supports, connections, are finishes, are structurally sound and collision‑free. When paired with 3D‑printed models, the team can visualize and resolve interface issues early, reducing field surprises and expensive rework.

Prefabrication Readiness

The analog-to-digital workflow moves smoothly from physical model to CNC and prefabrication. A printed prototype informs modular design decisions that streamline fabrication and installation—saving time, cost, and disruption.

Stakeholder Alignment and Confidence

There’s something powerful about walking decision-makers—including architects, GCs, and owners—through a tactile representation of the stairs. It fosters alignment, clarifies expectations, and locks in confidence long before construction begins.

HOW IT WORKS IN PRACTICE

Our 3D model fabrication produces a physical-scale printed stair that is layered, lifelike, and ready for hands-on review. The model can bring to life guardrail interfaces, tread profiles, and aesthetic finishes. Once complete, clients, collaborators, and Synergi’s team examine the model to catch visual issues, spatial conflicts, or material concerns long before fabrication begins. Insights gleaned from the prototype feed directly into shop drawings, prefabrication layouts, and installation plans, ensuring a seamless translation from model to reality.

BENEFITS OF UTILIZING 3D-PRINTED STAIR MODELS

- Sharper visualization leads to faster decisions.

- Reduced risk thanks to early conflict identification.

- Enhanced coordination among trades, minimizing site surprises.

- Faster approval cycles through clear, persuasive communication tools.

Synergi’s design‑assist framework seamlessly blends human expertise with cutting-edge tech.

3D‑printed stair models are a key component to a successful handover from design to construction, amplifying clarity and flagging issues early.

Take the Stairs, Clear Your Mind: A Simple Step Toward Mental Wellness