Overview

Our design-led team is best known for completing visually impactful, complex, and turnkey features with significant engineering challenges. For more than 35 years, Synergi has used its empirically developed design-assist methodology to collaboratively optimize design features with engineering or budgetary constraints for the world’s premier designers, developers, general contractors, and architects.

Design-Assist is a collaborative delivery method that capitalizes on the benefits of Synergi’s early engagement with the owner, design, and construction teams to improve constructability and reduce overall time and cost. Addressing concerns early in the design process enables the project’s key stakeholders to proactively develop a strategic building plan. Through our Design-Assist method, a project’s team can utilize Synergi’s specialty expertise to fill knowledge gaps in budgeting, materiality, and constructability, and to successfully achieve the delicate balance between creativity and constructability within the limitations of schedule and budget.

Glass Magazine Recognizes Synergi As Top U.S. Glazier

Learn MoreStrategy

Design-Assist is, at its core, a conversation between a project’s key stakeholders about vision, design intent, and constructability. During the Strategy phase, Synergi collaborates with a project’s design team and construction team to understand project constraints and design priorities, identifying potential risks to arrive at the highest quality and most efficient design possible. When budget is an issue, the Synergi team provides extensive benchmarking discussions to ascertain the priority of each item’s level of finish against achievability within the budget.

Synergi figured out a different way to fabricate and install that provided huge savings in both budget and install time but still met our design intent very closely. Finding ways to cut cost with fabrication and install methodology is a major expertise of Synergi.

— Kimberly SheppardPartner, Gabellini Sheppard Associates LLP

Concept Design

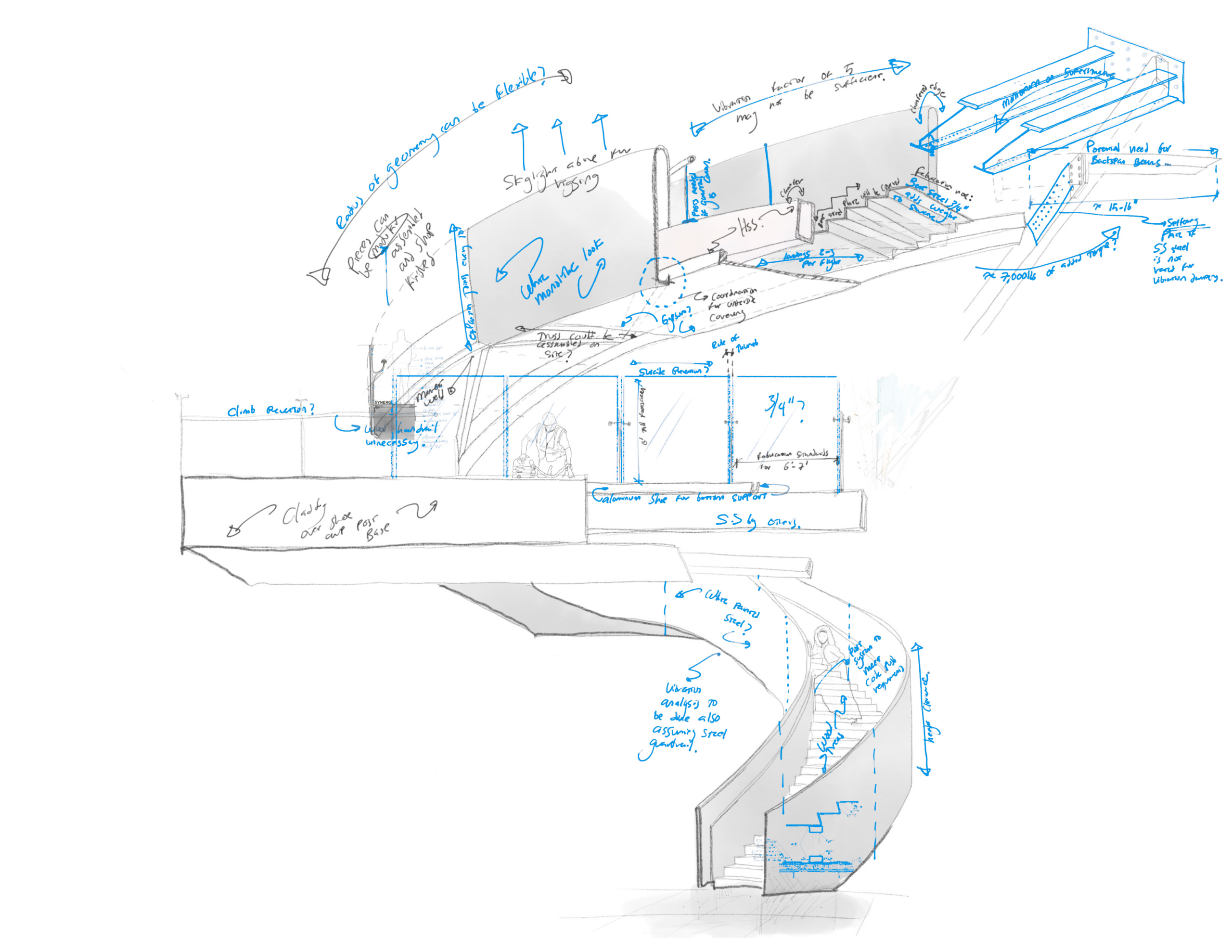

Concept design is a critical step where the strategy and design intent become a reality through Synergi's engineering team's creative design workshops with the project team. Identifying and developing solutions to each engineering hurdle is what creates a unique and stunning end project. As the project moves to Concept Design, the design and constructability aspects uncovered during the discovery phase are developed into schematic drawings. This enables a concept design to be established within 6-10 weeks, including confirmed preliminary engineering and Synergi’s commitment to a guaranteed maximum price within the project’s budget.

The deliverables for this phase include details that can be incorporated into project documents, as well as project mock-ups, 3D Printed stairs, and samples. 3-D printed models give an exciting first look into our stairs by bringing the architectural vision into focus. The tactile experience of maneuvering the model in any direction is one of many steps in our thorough preliminary design process that make ideas into reality. Synergi encourages “bringing the design to life” as early in the design process as possible and frequently fabricates full-size mock-ups and prototypes to better transform the design intent from paper to real life.

Engineering

During the critical Engineering phase of the Design-Assist process, the Synergi team verifies and confirms the constructability of the design. Synergi's in-house structural engineers are engaged from the outset to calculate structural components against building code requirements, performance standards, and constructibility requirements for each material. This phase identifies constraints early and reduces risk prior to design finalization so that costly reworks and supplemental structures are eliminated.

Documentation

The compact and focused Documentation phase allows the design development to keep momentum and the production of shop drawings to commence early. This provides early details that can be incorporated in the construction documents and shared with other early-release critical trades. Building Information Modeling (BIM) software is favored by Synergi for this phase – especially on complex architectural design, such as monumental feature stairs and guardrails – to verify the design with the structural model and other trades where interactions occur. This phase also includes the finalization of the work's lump sum construction cost and removal of all contingency costs.

We thrive on delivering demanding, multi-faceted projects to the highest standards, guiding you through a project from the initial brief to the grand unveiling.

— Synergi Team

Submittals & Procurement

The Submittals & Procurement phase can begin as early as concept design, solidifying decisions on materials and finishes and allowing the early release of critical pathways and long lead-time items. Engineering drawings, shop drawings, and product data are submitted for approval so materials can be procured, and fabrication processes can begin.

George Washington University – Milken Institute School of Public Health

Fabrication & Installation

At Synergi, we fabricate and install our materials internationally. Our early involvement means that we can share fabrication and installation insights early in the design, allowing prefabrication and modularization to be built into it. Synergi's craftsmen fit and form every element of the fabrication and our union and non-union crews perform installation across North America and the UK. We utilize our shop to produce full-size structural mock-ups, perform quality control testing, and do full-scale trial fittings before final fabrication, ensuring the delivered product is precision-fit to the most exacting standards. This enables us to execute a project seamlessly and to gain valuable LEED points!

Fabrication At Synergi