General

Strength In Every Step: Synergi’s Fabrication Story

From a small brass railing shop in 1986 to an industry leader in architectural stair fabrication, Synergi’s journey is a story of craftsmanship, innovation, and relentless growth.

In 1986, in a small Canadian workshop, a company called Accent Brass began fabricating railings for the restaurant trade. It was a modest operation, built on the belief that quality craftsmanship could set a business apart. With every piece that left the shop, there was an unmistakable commitment to precision, innovation, and the pursuit of something greater.

Accent Brass Delivery

As demand grew, so did the company. By 1994, Accent Brass evolved into Accent Architectural, expanding into a 25,000-square-foot fabrication facility to accommodate larger projects and more intricate designs. The team had outgrown its beginnings, but its passion for fabrication remained unchanged.

Accent Architectural fabrication facility in Canada

Over the years, Accent Architectural pushed the boundaries of what was possible in architectural metalwork. In 2015, after decades of perfecting custom railings, stairs, and ornamental metals, the company took on a new identity—Synergi, named after its first pre-engineered railing system. This rebranding was more than just a name change; it was a reflection of the company’s transformation into a comprehensive provider of architectural stair fabrication and specialty metalwork.

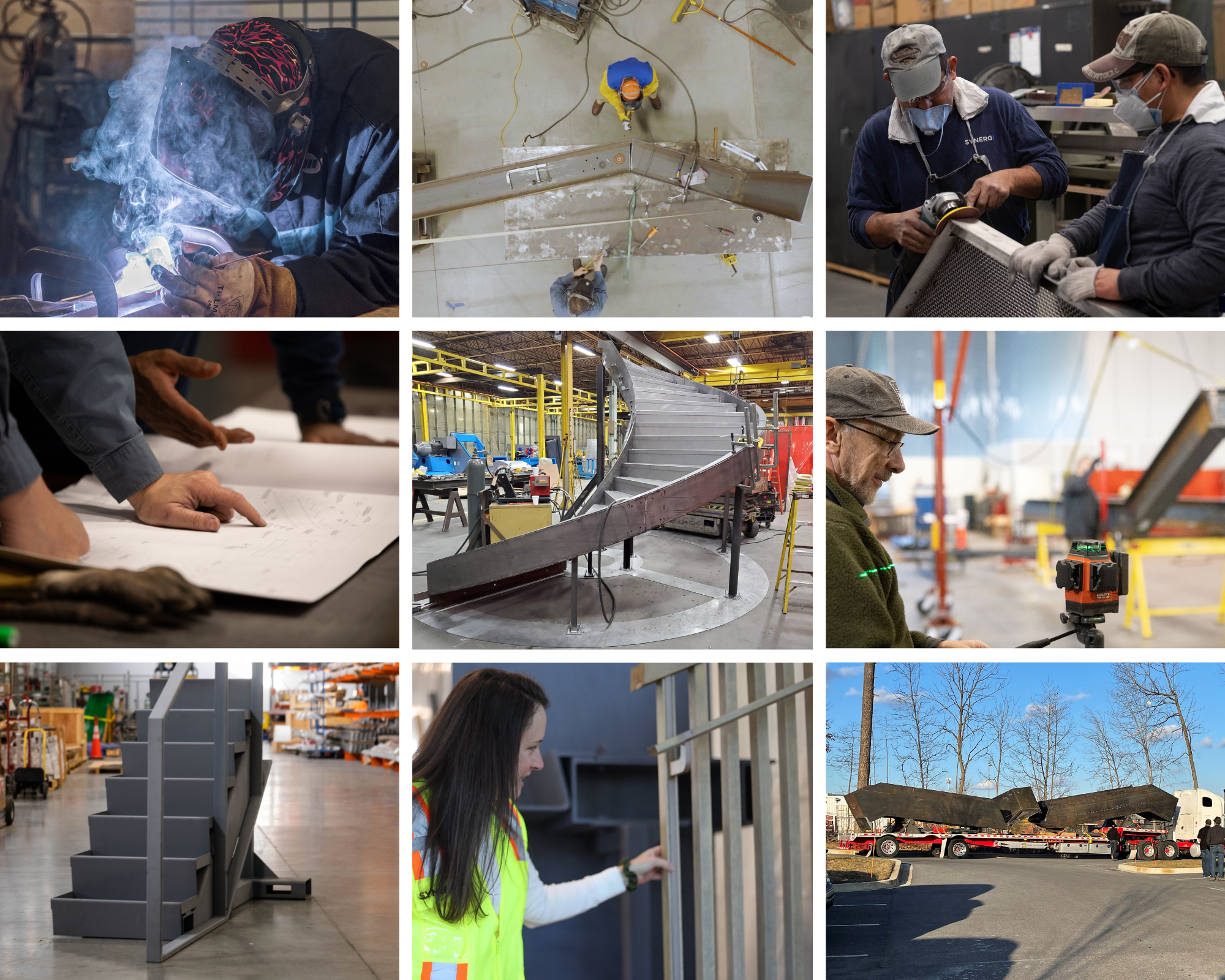

By 2019, Synergi’s growth demanded more space. To meet the increasing scale of its projects, the company moved its headquarters to Elkridge, Maryland, home to a state-of-the-art, 50,000-square-foot fabrication facility. Equipped with overhead crane systems, advanced welding and milling tools, 3D printers, and cutting-edge templating technology, Synergi was primed to take on some of the most complex and ambitious stair fabrication projects in the industry.

This commitment to excellence has been recognized through AISC certification—a prestigious industry accreditation that sets the highest standards for structural steel fabrication and construction. Additionally, Synergi’s welders hold certifications from the American Welding Society (AWS), ensuring that every project meets the highest levels of precision and durability.

Synergi’s 50,000 sqft. fabrication facility in Elkridge, Maryland.

Today, with international offices and fabrication facilities, Synergi continues to grow, taking its innovative spirit to new heights. What began as a small fabrication shop has become a leader in architectural stair fabrication, railings, and ornamental metals. Yet, at its core, Synergi remains true to its roots—the unwavering belief that craftsmanship, quality, and innovation will always set it apart.

One stair. One project. One partnership at a time.

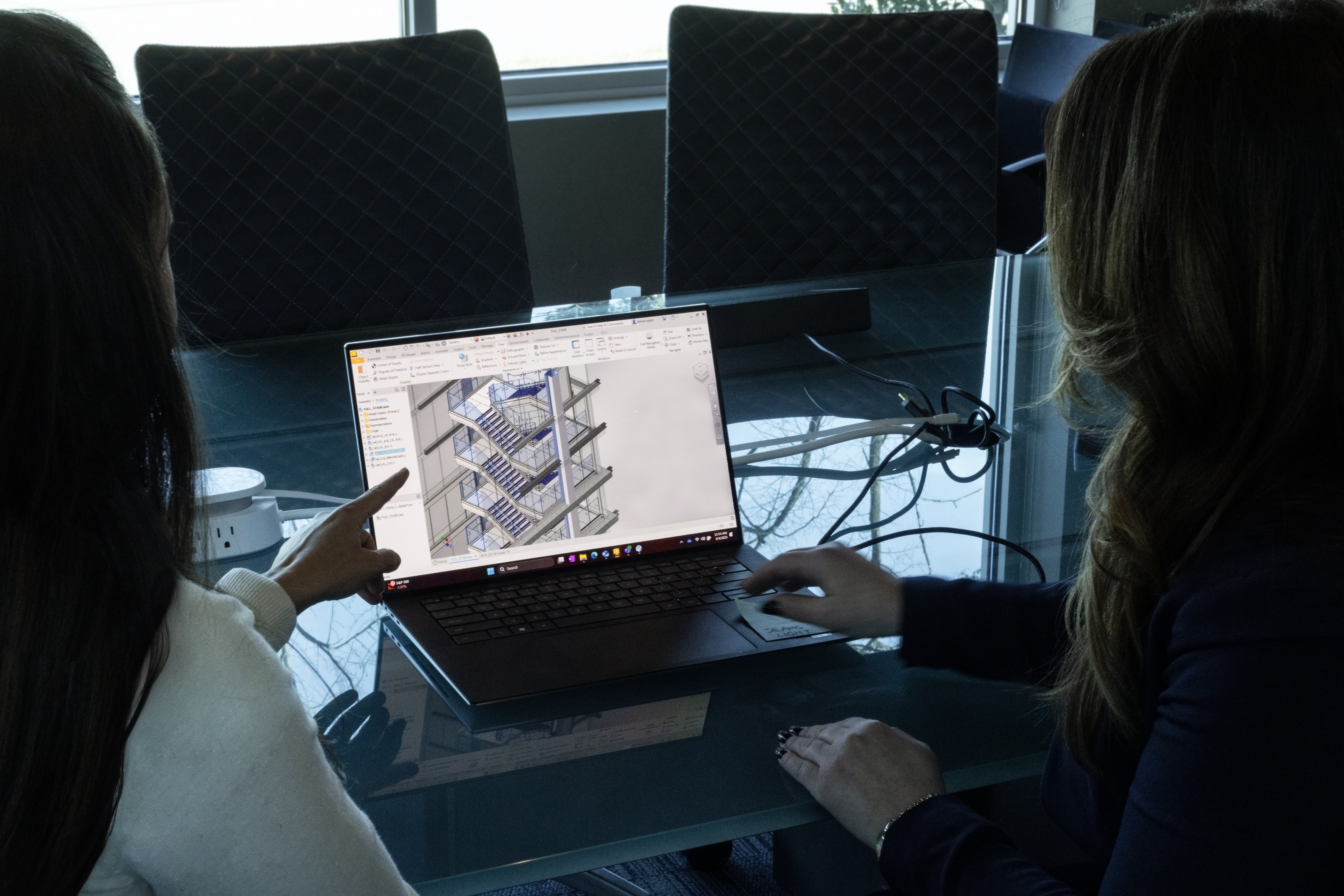

Hear From Two Synergi Women Bringing Expertise and Leadership to Architectural Stairs