Sustainability

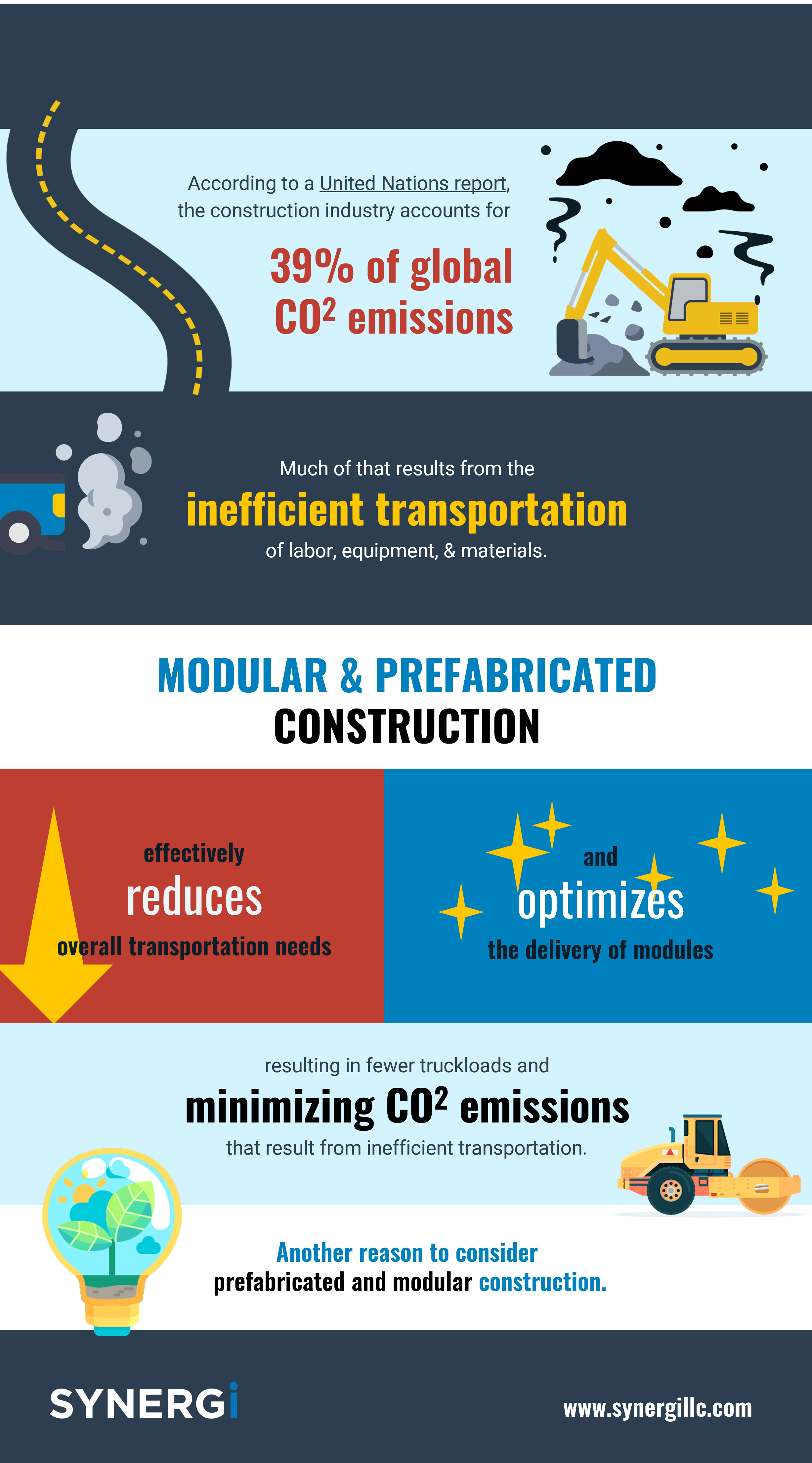

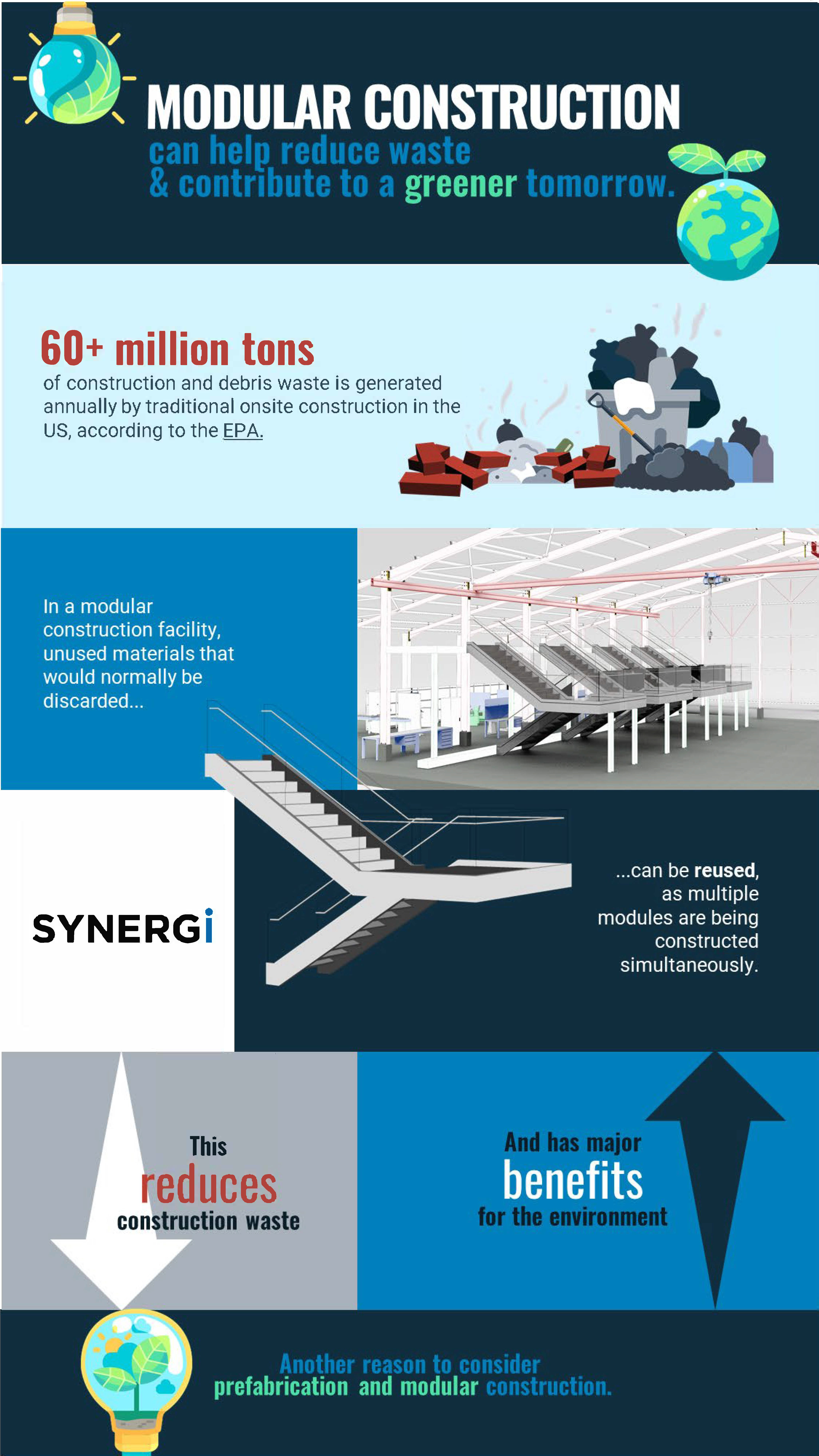

For over 30 years, Synergi has designed, fabricated, and installed railing systems and architectural products comprising of metal, glass, stone, and wood. As the fabrication of these components is historically associated with significant carbon output, Synergi has given major consideration to how to operate in an environmentally sustainable manner and makes every effort to reduce the carbon footprint of our projects. In an industry that’s notoriously problematic for the environment, we’re committed to delivering impactful solutions.

As our business keeps growing in scale and influence, we’re harnessing our unique capabilities in engineering and design to be a positive force of change.

A Better Tomorrow

For over 30 years, Synergi has designed, fabricated, and installed railing systems and architectural products comprising of metal, glass, stone, and wood. As the fabrication of these components is historically associated with significant carbon output, Synergi has given major consideration to how to operate in an environmentally sustainable manner and makes every effort to reduce the carbon footprint of our projects. In an industry that’s notoriously problematic for the environment, we’re committed to delivering impactful solutions. As our business keeps growing in scale and influence, we’re harnessing our unique capabilities in engineering and design to be a positive force of change.

We believe that we have an obligation to operate in a sustainable manner to benefit not only the environment, but to best serve our clients and partners, secure profits, and drive long-term prosperity.